Use Of Conductivity As A Tool For On-Site Residue Management And Definition Of Smart Cleanroom Regimes

By Dr. Andreas Krause, Matthew Cokely, Laura Brennan & Aneta Schimanowitz - Ecolab Life Sciences, UK

The naked eye can be deceiving when assessing surface cleanliness. Regulatory bodies are increasingly scrutinizing surface residues left by cleaning and disinfection products, driven by concerns highlighted in the updated EU GMP Annex 1 and recommendations from the PDA Journal of Pharmaceutical Science and Technology. These residues can pose significant risks to product quality and patient safety, potentially leading to cross-contamination and adverse material interactions. While the industry has relied on visual assessments for years, this subjective method often falls short in detecting the true extent of residue buildup.

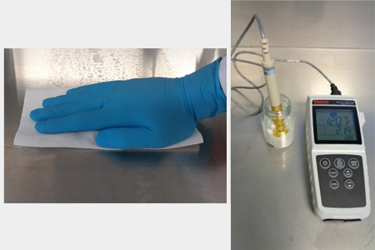

Now, a new, pragmatic method offers a scientific approach to residue quantification: conductivity measurement. This technique allows for on-site assessment of disinfectant residues, providing a rapid and objective evaluation of surface cleanliness. By measuring the conductivity of residues, manufacturers can gain a clearer picture of their disinfection effectiveness and optimize their cleaning regimes.

Want to learn how conductivity measurements can optimize your cleanroom residue management? Keep reading to discover how this method can replace subjective visual assessments with objective scientific data.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.