Use Of Nunc Cell Factory Equipment To Accelerate Workflows And Increase Product Consistency

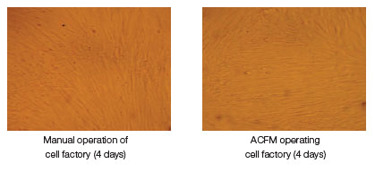

Scaling up adherent cell culture can be a difficult process for many vaccine, cell therapy, gene therapy, and viral vector manufacturers. Some cells can alter their properties if they are not cultured in specific conditions. Using multiple issue culture flasks with the same culture conditions comes with a host of its own concerns, including batch-to-batch inconsistency, increased probability of contamination, and labor intensification. The simplest way to mitigate all these risks is by using a multi-layered vessel, such as the Thermo Scientific™ Nunc™ Cell Factory™ system, in a closed system with automation equipment. The Nunc Cell Factory equipment automates the filling, emptying, harvesting, and trypsinization steps of adherent cell culture to help realize consistency, optimization, and standardization. This combination of equipment ensures a quick scale-up solution for quality product.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.