ABOUT US

Weiler Engineering is America's leading provider of aseptic Blow/Fill/Seal liquid packaging machines for pharmaceutical and healthcare applications. Continous innovation and incorporation of the latest technological advances in equipment design and systems assure our customers of the highest level of quality in the production of sterile liquid products.

Since 1959, Weiler has brought innovation in design, development, technology, validation and regulatory science to each project. We are committed to the highest standards of excellence and to further expanding our products and systems to enhance patient care.

CONTACT INFORMATION

Weiler Engineering, Inc.

1395 Gateway Drive

Elgin, IL 60123

UNITED STATES

Phone: 847-697-4900

Fax: 847-697-4915

Contact: Andy Goll

FEATURED ARTICLES

-

Learn how Blow/Fill/Seal technology supports contamination control, reduces operator risk, and meets sterility assurance requirements under dynamic conditions with advanced airflow and monitoring.

-

This video demonstrates Weiler Engineering Inc.’s LVP Bottle Deflashing machine processing 500ml LVP bottles from our 14-cavity mold and blow fill seal (B/F/S) machine.

-

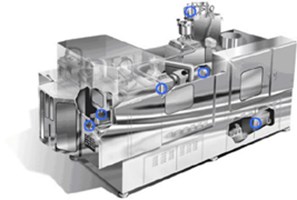

A 3D Animation production of Weiler Engineering, Inc.'s B/F/S (Blow/Fill/Seal) aseptic filling equipment with downstream remote deflasher.

-

Despite the benefits of B/F/S over glass, some pharmaceutical companies refuse to make the switch. Explore how an investment in B/F/S may yield incredible long-term savings.

-

As the industry continues its move toward biologics, innovative solutions and technologies will be needed to ensure a safe and reliable approach to the manufacturing and delivery of these drugs.

-

The aseptic blow-fill-seal (B/F/S) process has proven to be an ideal system for the creation of a wide variety of container shapes and sizes used for packaging sterile pharmaceutical liquids.

-

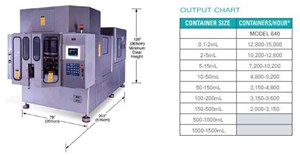

ASEP-TECH Blow/Fill/Seal machines are designed and manufactured by Weiler Engineering offers a unique combination of world-class engineering, leading-edge automation and process design, assures years of reliable, high quality production.