FEATURED ARTICLES

-

U.S. Pharma Tariffs And MFN In 2026: Manufacturing And Procurement Impact

Beroe Inc.'s Mathini Ilancheran discusses the 2025 U.S. pharma tariff framework and translates it into actionable procurement and outsourcing responses.

WHITE PAPERS & CASE STUDIES

-

Converting From A Spray-Dried Dispersion To A KinetiSol Formulation In <5 Months

A development team quickly turned a low‑bioavailability, high‑burden formulation into a streamlined, clinically improved version, boosting exposure, simplifying manufacturing, and accelerating progress.

-

Patient Adherence With A Novel Dosage Form

A sprinkle formulation helps patients with tremors or dysphagia take medication more easily, improving adherence, comfort, and care through a novel, FDA-approved oral granule format.

-

A Powerful Non-Destructive Tool For Tablet Characterization

Discover how X-ray micro-CT provides vital, non-destructive analysis of a tablet’s internal 3D physical structure. This structural insight is essential for troubleshooting defects and confirming performance.

-

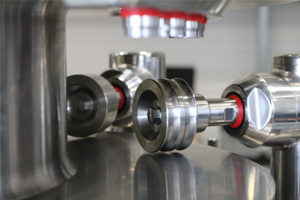

Optimizing DPI Production: Filling Technologies For Precision And Performance

Developing effective dry powder inhalers requires expertise across multiple disciplines, from particle engineering and device technology to manufacturing science and regulatory knowledge.

-

How To Avoid Sticking And Picking In The Tableting Industry

Review strategies to mitigate sticking and picking risks in the tablet industry, and learn how you can foster improved tablet production processes, ensuring higher quality and consistency.

-

Overload Setting – Tricks And Techniques

Learn how a partner company that is committed to assisting manufacturers with calibration and optimal set-point establishment can serve as a valuable resource in achieving optimal tablet production.