ABOUT ANRITSU - PRODUCT INSPECTION & DETECTION

As part of the Product Quality Assurance division of the Anritsu Corporation, we excel in the advancement of quality control programs with high-performing and reliable solutions globally.

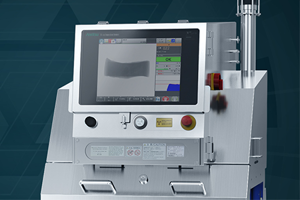

Our X-Ray Systems, Checkweighers, Metal Detectors, Combo Systems, Rejectors, and QuiCCA Software provide a superior ROI and ensure compliance with stringent quality control programs while protecting your brand. Our local branches in the US, Europe, Brazil, and Mexico are equipped with in-house service & parts dept., we deliver, install, and maintain in record time. With over 200,000 installations, we are the brand that is trusted to protect the safety and security of your customers.

What we stand for

There is no greater priority than the safety and security of your customers. For nearly half a century, our commitment to developing unique inspection solutions of the highest value have advanced food and pharma industries and assured consumer safety. It’s our goal to continue a level of precision, reliability and support that truly advances the quality of your product and the efficiency of your operations.

ANRITSU'S SOLUTIONS

Explore an overview of Anritsu's solutions for the pharmaceutical industry.

CONTACT INFORMATION

Anritsu - Product Inspection & Detection

701 Innovation Drive

Elk Grove Village, IL 60007-2453

FEATURED ARTICLES

APPLICATION NOTES

-

Learn how multi-lane checkweighing boosts operational efficiency, ensures accurate dosing, and simplifies changeovers, making it ideal for applications like dual-chamber sachets and nutraceutical products.