FEDERAL EQUIPMENT COMPANY

Federal Equipment Company is a reliable resource for pharmaceutical processing and packaging equipment needs, with over 60 years of expertise working with manufacturers seeking to buy and sell used equipment.

For companies with surplus equipment, Federal Equipment Company takes away all the headaches of asset management. We bring deep knowledge of equipment values, supporting accurate appraisals, and advise you on a range of options to optimize the value you recoup. We also offer cash liquidity and fast, expert removal of individual pieces to entire lines – protecting your facility.

This activity with reputable companies gives us a continual on-hand inventory of reliable equipment manufactured by leading OEMs. Our market knowledge ensures you buy exactly what you need with fast turnaround. We also offer expert training & troubleshooting for solid dose equipment.

ORAL SOLID DOSE TRAINING RESOURCES

-

Master the art of tablet manufacturing with our comprehensive hands-on seminar, designed to equip you with in-depth knowledge and skills required for pharmaceutical and supplement manufacturing. This two and a half-day course covers essential topics such as tablet press setup, powder preparation, formulation, excipients, API, direct compression, wet granulation, dry granulation, tablet press operation, compaction, lubricants, and quality control.

-

Introducing Solid Dose Manufacturing Process Training, a comprehensive three-day course designed to equip you with the essentials of creating high-quality tablet and capsule oral solid dosage forms. Limited to 24 participants, this hands-on course ensures a more intimate learning experience tailored to each attendee's needs. Discover the techniques that will assist you in enhancing your development and scale-up operations in the pharmaceutical industry.

-

Immerse yourself in this comprehensive two-and-a-half-day training event that focuses on two-piece hard shell capsule filling for pharmaceutical and supplement manufacturing. Learn about the encapsulation process, common equipment, terminology, and gain practical knowledge with hands-on breakout sessions.

-

Film Coating Technologies is a two-and-a-half-day training event focused on batch, continuous and Wurster technologies used to coat tablets, hard shell, and softgel capsules.

We will walk through the entire process of preparing the solutions, cleaning and setting up the equipment, calibration and run several batches of different tablets and capsules.

We will provide an explanation of each step in the process, common terminology, and provide practical knowledge of each topic. Hands on breakout sessions will be part of this course!

-

Granulation Technologies is a two-and-a-half-day training event focused on various granulation methods used in the pharmaceutical industry to create uniform, high-quality granules for tablet and capsule production.

We will cover the entire process, from raw material preparation to the final granulation step, including cleaning, setting up equipment, and running multiple batches using different techniques. Hands-on breakout sessions will be a crucial part of this course, providing participants with practical experience.

PACKAGING EQUIPMENT

-

Used Omega shrinkbundler, model DL-27, speeds up to 26 bundles/minute or 150 containers/minute, package size capabilities 2 X 1 X 3, 6 X 1 X 1 and 3 X 1 X 1, bundle designation 12 cnt, 32 cnt and 60 cnt, with 30" wide x 11" high x 24" long heat tunnel, 480 volt, stainless steel frame, serial# 00-J26973, new 2000.

-

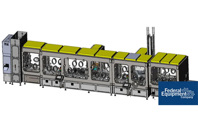

Used Uhlmann thermoforming blister packaging line, built in 2004, consisting of: - Uhlmann UPS4 ETX blister machine, with dual pick-and-place style feeding stations, vision system, rated up to 50 cycles per minute, deep draw design, 140mm x 39mm max. blister format, serial# 69/0515. - Uhlmann C2155 cartoner, rated up to 150 cartons per minute. 115mm x 100mm x 170mm max. carton size. serial# 103/117. -Uhlmann E4040 case packer, rated up to 10 cases per minute, serial# 102/107.

-

Used IMA bundler wrapper, model ES500BD, speeds up to 30 bundles/minute, with infeed and outfeed conveyors, with shrink tunnel, approximately 19.5" wide x 32" long x 8' high, IMA serial# 4355, built 1988.

-

Used Omega single lane bundler, model SL-18, speeds up to 20 bundles/minute, up to 190 containers/minute, formats 3x2x1, 4x3x1, 6x4x1, 17" film width with integrated heat tunnel and feed conveyor, stainless steel frame, 240 volt, serial# 95-J19692, built 1995.

-

Used Pester bundler, model PEWO-Fold1, serial# 10183, built 2000.

-

Used Multipack stretch bander, model F40, capable of speeds up to 30 bundles/minute, bundle dimensions, 30-350 mm long x 12-200 mm high x 50-300 mm wide, with powered film tension control, 6" wide x 40" long feed belt, serial# 95060, built 1995.

-

Used Klockner blister packaging line with model CP1200 blister filler sealer, model P3000 cartoner, CP1200 serial# 017, P3000 serial# 036, built 2000.

-

- SKU: 4515-1

- Category: Packaging Lines > Liquid

- Manufacturer: Cozzoli

- Location: Kansas

-

Used Mettler Toledo pass thru metal detector, model V4-RAD, approximately 650mm high x 150mm wide opening, CE rated, 240 volt, on stand.

-

Used Uhlmann blister packaging machine, model UPS4, unit includes unroll stand, chiller for cold forming, Aylward feeder, vision system, Gottscho, model 812-10 printer, 480 volt, Uhlmann serial# 401, built 1994.

-

Used Avery Syringe Labeler, model ALS-330R label head, with integrated 11" wide x 10' long roller conveyor, stainless steel housing with Allen Bradley plc controls, serial# 08870-01-0188, built 1995.

-

Used Nikka Densok pinhole inspector with feed tray, timing feed screw, currently set up for 2 ml vials on stand.

-

Rebuilt ALPS (Automated Liquid Packaging Solutions), blow fill seal machine, model 301 BFS. Currently comes with 10 mL tooling, with vial size of approximately 63.3mm high x 18.6mm wide x 17.8mm deep cavities. Machine rated for 1 mL (4,500 units per hour) - 1,000 mL (400 units per hour) fill capacity depending on container size and product specifics. Includes integrated extruder with pellet hopper, bottle forming, filling, parison head and knife, bottle discharge and sterilization piping in one machine base, PLC controls with HMI touchscreen, machine# 4030, built 2012, refurbished by ALPS and unused.

-

Used Uhlmann horizontal cartoner, model C 2205, speeds up to 250/ minute, 150 mm x 100 mm x 90mm max cartoner size, dual blister feeder stations, with (1) powered and (1) drop feeder, Laetus scanner, 3/60/480, serial# 104, built 1994.

-

Used IMA cartoner, model IC150C, speeds up to 120 cartoners/minute, designed for pre glued cartons, 28 mm wide x 12 mm high x 55 mm long minimum carton size, 92 mm wide x 60 mm high x 190 mm long maximum carton size, with blister feeder, with leaflet inserter, Allen Bradley Micrologix 1500 plc with Panelview 550 HMI, Machine# B-92-024, built 2005.

-

Used IWKA fully automatic continuous motion horizontal cartoner, model CPS-R Cartopack, capable of speeds up to 300 cpm, adjustable three chain machine on 6" centers for a carton size range: (length) 25 - 125MM longx 16 - 80MM wide x 55 - 180MM deep, Nordson 3100 Hot melt glue system, 3' long carton magazine with Siko guage adjustment, three head rotary carton feeder, 8' long adjustable bucket infeed system, presently set up to accomodate Guk sheet fed leaflet feeder for "U" type leaflet insertion, equipped with dual blister feed system and was last running blisters in an OTC pharmaceutical operation, 460 volt, serial# 279, built 1998.

-

Used BellatRx electronic lane counter, model RX-Fill PLUS, speeds up to 25 bottles/minute at 100 count, 2-40mm tablet size, 1" - 4" by 12" high bottle size, 0.5" or larger neck diameter, Allen Bradley PLC controls with PanelView 600 HMI, 120 volt, order# 7155, serial# 035, built 2019.

-

Used Brevetti vial inspection unit, model A1, speeds up to 360 pcs/hour, currently set up for 53.5 mm diameter 100 mL vails, 8mm - 95 mm diameter x up to 240 mm high vial size range, with integrated robotic arm, (4) inspection units, with vial feed infeed and acceptable exit tables, dual reject stations, with HMI panel, serial# BM242, built 2016.

-

Used IMA Flexfill Series monoblock filler/plugger/capper, model F940 filler, serial# RE1003, stainless steel product contact surfaces, capable holding up to 8 fill heads (currently set up for 6 fill heads), 20 - 90 mm diameter x 40 - 180 mm height vial size range, includes model F572 plug/pump inserter, serial# 572031, vibrating hoppers and bowl feeders, mounted under Laminar flow fume hood, built 2003.

-

Used Thermo Scientific Checkweigher, model Versa RX, 304 stainless steel construction, with pneumatic reject, touchscreen HMI, approx. 2,200 hours of use, with 6" wide infeed/outfeed conveyor, 115 volt, serial# A626, built 2014.

-

Used Safeline metal detector, model PHARMXSR4V1/26X22, module serial# 32625, serial# 13123.

-

Used Klockner medipak blister packaging unit, Model EAS.

-

Used Filamatic Cubitainer bag in a box liquid filling system, rated up to 10 containers/minute, stainless steel product contact surfaces, with twin head filler with MicroMotion flow meters, neck positioning clamps, chain conveyor, twin head single chuck capper station with bowl cap feeder, Farason Cubitainer handling feed system, with Hytrol feed and discharge conveyors, previously filling 20 liter cubitainers, Fillamatic serial# 021707, built 2007.

-

Used Adtech syringe filler, SO# 725, with visual inspection system, capper feeder, Allen-Bradley PLC and interface, built 1989.

-

One (1) used Uhlmann blister packaging machine, model UPS 300, with HAPA ProntoPhot printer, type 203, serial# 20832, Uhlmann serial# 491, built 1988.

-

Used Klockner blister packaging line with model CP1200 blister filler sealer, model P3000 cartoner, and Scandia bundler, CP1200 serial# 017, P3000 serial# 036, built 2000.

TABLET PRESSES

-

Used Kikusui tablet in tablet press, model Aquarius G-J/DC, 36 station, keyed upper punch guides, B tooled, 100 kN pre-compression, 100 kN main compression, 16mm max tablet diameter, 18mm max depth of fill, rated up to 259,200 tablets/hour, with DC module for core feeder, 4-15mm core depth adjustment, with integrated primary and secondary powder feed hoppers, and core feed hopper, project# 1-6302, built 2009.

-

Used GlobePharma Single Station Tablet Press.

-

Used Elizabeth Hata R&D tablet press, model EP200, B/D tooled with 10 station turret, 5 stations each B and D, 16 mm B, 22 mm D max tablet diameter, 17 mm B, 18 mm D max depth of fill, rated up to 6000 tablets/hour, with feed hoppers and feed frames, Machine #81, built 2011.

-

Used Sejong rotary tablet press, model GRC-15C, 15 station, D tooled, 6 kn main compression, 2 kn pre compression, 25 mm max tablet diameter, 22 mm max depth of fill, with feed hoppers, rated up to 67500 tablets/hour, with integrated controls and touchscreen interface, serial# ST17866, built 2017.

-

Used Elizabeth Hata HT-X65LD-U Tablet Press, 65 Station, BB-tooling, 8 ton pre and main compression, Keyed Upper Punch Guide, Dual Sided, Force Feeders, 13MM max tablet diameter, 18MM max depth of fill, 624,000 max TPH output, Feed hopppers, Control Panel, S/N: 2038.

-

Used Sejong rotary tablet press, model GRC-15C, 15 station, D tooled, 6 kn main compression, 2 kn pre compression, 25 mm max tablet diameter, 22 mm max depth of fill, with feed hoppers, rated up to 67500 tablets/hour, with integrated controls and touchscreen interface, serial# ST17866, built 2017.

-

Used Elizabeth Hata R&D tablet press, model EP200, B/D tooled with 10 station turret, 5 stations each B and D, 16 mm B, 22 mm D max tablet diameter, 17 mm B, 18 mm D max depth of fill, rated up to 6000 tablets/hour, with feed hoppers and feed frames, Machine #81, built 2011.

-

Used Kilian rotary tablet press, model T100, 16 station, B/D IPT turret, with (8) B tooled, 16 mm diameter, 16 mm depth of fill and (8) D tooled, 25 mm diameter, 16 mm depth of fill stations in single turret, with additional 9 station IPT B toolded turrent, 42 Kn pre-compression, 65 Kn main compression, keyed upper punch guides, singled sided with force feeder, commission# 706849, built 2002.

-

Find all the equipment used to make solid dose tablets and other compressed materials right here. Federal Equipment Company offers used tablet presses and equipment to fully complete the tablet manufacturing process – used rotary and single station tablet presses, used tablet dedusters, used friability testers, used hardness testers, used metal detectors, used tablet printers, and an assortment of used tablet press turrets and parts.

-

Used Kilian rotary tablet press, model T100, 16 station, B/D IPT turret, with (8) B tooled, 16 mm diameter, 16 mm depth of fill and (8) D tooled, 25 mm diameter, 16 mm depth of fill stations in single turret, with additional 9 station IPT B toolded turrent, 42 Kn pre-compression, 65 Kn main compression, keyed upper punch guides, singled sided with force feeder, commission# 706849, built 2002.

-

Used Elizabeth Hata HT-X32-MS-U Tablet Press, 32 Station D Tooled, Keyed Upper Punch Guides, Single Sided, Force Feeder with Hopper, Controls, Serial# 250, Controls Upgraded 2018. S/N: 250.

-

Used Manesty Nova IPR Tablet Press, Model Nova, 51 Station, Keyed Upper Punch Guide, Single Sided with Force Feeder and Feed Hopper, External Panel, Manesty Serial# 15629-86.

-

Used Korsch XL 400 2-Layer rotary tablet press. 35 station with B turret, 29 station with D turret. Serial# K1500036, built 2001.

-

Used Kikusui Virgo 519 KRCZ rotary tablet press 19 station, 3 ton pre-compression, 5 ton main compression, keyed upper punch guides, 16 mm max tablet diameter, 16 mm max depth of fill, single sided with hopper and gravity feeder, rated up to 75600 tablets/hour, with control panel, serial# 1-3743, built 3/1993.

-

Used Manesty Unipress rotary table press, model MFG 765, 27 station, keyed upper punch guides, 6.5 ton main compression, 1 ton pre compression, B tooled, 16 mm max tablet diameter, 18 mm max depth of fill, single side with force feeder with feed hopper, with control cabinet, up to 196,200 tablets/hour, serial# 15578 85.

-

Used Manesty Unipress rotary table press, 34 station, keyed upper punch guides, 6.5 ton main compression, 1 ton pre compression, B tooled, 11 mm max tablet diameter, 18 mm max depth of fill, single side with force feeder with feed hopper, with control cabinet, up to 247,200 tablets/hour, serial# 15458 84.

-

Used BWI Manesty Unipress Diamond rotary table press, 27 station, keyed upper punch guides, 6.5 ton main compression, 1 ton pre compression, B tooled, 16 mm max tablet diameter, 18 mm max depth of fill, single side with force feeder with feed hopper, rated up to 196,200 tablets/hour, serial# UN248JA.

-

Hata Tablet Press, Model HT-AP55-DU/I.E. Double sided, serial number Nov. 90 - Oct. 1991

-

Used Key International single station bench top tablet press, model: SC-2. 1.5 ton compression pressure, approximately .5" max tablet diameter, .5625" max depth of fill, manual operation, serial# JI4786.

-

Used Korsch rotary tablet press, model PH250/25, 25 station, 20 Kn pre compression, 80 Kn main compression, 16 mm max tablet diameter, 18 mm max depth of fill, single side with force feeder, rated up to 180000 tablets/hour, serial# 1.0031.94, built 1994.

-

One (1) used Elizabeth Hata Elizatest Auto Sampler, model 3+, with (8) sample stations, with Mettler-Toledo scale, disposal bin, serial # ET3089707007

-

Unused Stokes 560 tablet press tooling, tooling size: 3650 x 7850 inch Caplet, 44 Lower Punch/44 Upper Punch/44 Die, manufactured by Natoli.

-

Used Korsch rotary tablet press, model PH106-DMS, 6 station, 40 KN compression pressure, keyed upper punch guides, 15 mm max tablet diameter, 15 mm max depth of fill, force feeder with feed hopper, rated up to 32,400 tablets/hour, with control panel, machine# 1.0062.95.

-

Used Manesty Drycota rotary tablet press, 16 stations, keyed upper punch guides, 13/16" maximum coated tablet diameter, 9/16" maximum diameter core, 3/16" maximum depth of fill on core with 7/16" maximum depth of fill on coated tablet, rated up to 664 tablets per minute, serial# 387556, 38656.

-

Federal Equipment Company offers a used Korsch XL 400 2-Layer rotary tablet press. 35 station with B turret, 29 station with D turret. Serial# K1500036, built 2001. Product specifications include: Compression Force: 10; Depth Of Fill: 18 mm-B / 22 mm-D; Estimated Shipping Dimensions: 64" x 38" x 88" main press.

-

100 Kn main compression with 100 Kn precompression, "B" tooled, dual-sided, 16 mm max tablet diameter, 18 mm max depth of fill with single layer, bi-layer capable with 16 mm max depth of fill, 10 mm max second layer depth of fill, speeds up to 766,800 tablets/hour single layer, 383,400 tablets/hour bi-layer. Includes spare turret and control panel. Serial # K1580006, built in 2003.

-

Used Korsch XL 800 rotary tablet press, 87 station. 100 Kn main compression with 100 kN pre-compression, "BB" tooled, dual sided, 13 mm max tablet diameter, 18 mm max depth of fill with single layer, bi-layer capable with 16 mm max depth of fill, 10 mm max second layer depth of fill, speeds up to 939,600 tablets/hour single layer, 469,800 tablets/hour bi-layer, with electrical panel, serial# K1580003, built 2002.

GRANULATORS & FLUID BED DRYERS

-

Used Globe Pharma high shear granulator, model GPHSG-5, with 1, 3 and 5 liter stainless steel bows, 1 hp, 110 volt, main blade motor, with removable top mounted chopper, serial# 052237829, built in 2022

-

Used GEA Niro sanitary spray drying system consisting of: Model PSD4 GEA Niro spray dryer, approximately 8' inner diameter x 8'6" straight side x 8'9" deep cone bottom spray dryer chamber, 316 stainless steel product contact surfaces, mirror internal finish, with fluid nozzle and centrifugal rotary atomizers, approximately 17" diameter, sanitary stainless steel cyclone fines collector, approximately 6' diameter dust collector, sanitary stainless steel construction, pulse jet, cone bottom, set up for electric or steam heating with Watlow, 145 kw electric heater with external Hepa filter, air handler with steam coil and Watlow 37.25 kw electric heater, internal Hepa filter, designed for nitrogen purge, 7.5 hp process air supply blower, 7.5 hp process air return blower, set up for solvent recovery with condenser(less receiver pot), solution feed pump with Micro Motion flow meter, inter connecting pipe work from dryer, to dust collector and cyclone, GEA Niro control panel and HMI panel, 460 volt, 3 phase, GEA Niro fabrication# 099-0013-00, built 1999.

-

Used Niro fluid bed dryer granulator, model MP1, stainless steel construction, 10 bar internal shock pressure with misc chambers, air handling, blower and controls, serial# 05305-1320, built 2005.

-

One (1) used Vectro granulator, mdoel CF360EX, stainless steel construction, 3-5 kg capacity, xp design with controls, 220 volt, serial# CF-110, new 1982.

-

One (1) used Fluid Air fluid bed dryer granulator, model 0020, 316 stainless steel product contact parts, currently set up with dryer chamber, chamber designed to handle Wurster coating with change parts, electrically heated with 12 kw heater, blower, with on board plc controls with HMI interface, 575 volt, serial# 10169, built 1999.

-

Used Glatt GPCG 3 Fluid Bed Dryer Granulator, wurster, top spray granulation and rotor granulation inserts with bowls, 2.2 kw blower, 220 volt with controls.

-

Minimally used Glatt GPCG 15 SC fluid bed dryer granulator. Design is 3 Bar Pressure Shock rated for aqueous processing only. SC, or Super-Clean, Design. Featured with stainless cartridge air pulse exhaust filters, includes legacy PLC based control system with HMI, CIP Skid with pumps, automatic valves, tanks, detergent dosing, loose CIP piping and cleaning nozzles, inlet AHU with electric heat, duct flaps, process tower with top spray granulator/dryer bowl.

USED BIOPHARMA EQUIPMENT

-

Unused 3,000-liter Thermo Scientific imPULSE single-use mixer, stainless steel construction, bottom-mounted imPULSE mixing technology, jacket-heated tank, BioTitan single-use bag system, integrated pH/DO/CO₂ / temperature / weight / conductivity/pressure sensors, touchscreen e-box controls, caster base, linear scalability, 1% minimum mixing volume.

-

Unused 5,000-liter Thermo Scientific imPULSE single-use mixer, stainless steel construction, bottom-mounted imPULSE mixing technology, jacket-heated tank, BioTitan single-use bag system, integrated pH/DO/CO₂ / temperature / weight / conductivity / pressure sensors, touchscreen e-box controls, caster base, linear scalability, 1% minimum mixing volume.

-

Unused Turn-Key Modular Systems (TKMS) Tangential Flow Filtration (TFF) system. This TFF unit is designed to remove ethanol from the process stream (via diafiltration, where a buffer exchange occurs to a required number of diavolumes). The system consists of: - UF Filter: Repligen model KROSFLOW MAX X06-E100-05-N for solvent removal and buffer exchange, CIP and SIP rated, 12,000 fiber count, 128,000 square-centimeter surface area (12.8 square-meters). - Filter cartridge & housing: Allegheny Bradford Corp. Model OC-1-01-QT49394-2 Air and Clean Steam Filter, 316L SS construction, design pressure FV to 150 psig, design temperature -20 to 350F (SIP temp approx. 121C). - Feed Pump: Waukesha Cherry-Burrell model 220-U2 positive displacement pump (100 lpm min/ 600 lpm max) - GEMU, Steriflow , and PBM valves - Optek UV Analyzers (not Ex rated) - Instrumentation: Bronkhorst, Endress & Hauser, and others - Sample holder: Millipore model AT51/5-3E0 - Aflex Hose - 316L stainless steel product contact parts - Stainless steel skid frame - Built to comply with "ATEX Zone 2 II 3G Ex" standards - FAT performed still on original shipped skid from OEM.

-

Applied Biosystems genetic analyzer, model 3500, integrated autosampler, 120 volts, serial# 24158-161.

-

Malvern 2000 Laser Diffraction Particle Size Analyzer with (1) Malvern Model Scirocco 2000, Dry Power Tray Sampler, and (1) Malvern Model Hydro 2000S, Liquid Test Module.

-

Used Shimadzu X-Ray Diffractometer, model XRD-6000, 220 volt, serial# Q30344800678 CZ

-

Rigaku Miniflex X-Ray defractor, (6) sample capacity, water cooled, 115 volts, serial# TD01111.

-

Used 150 liter Feldmeier reactor, 316 stainless steel construction, removable dish top, dish bottom, rated 50 psi and full vacuum at 400 f internal, jacketed for 150 psi and full vacuum at 400 f, bottom mounted agitator drive, on legs, serial# S07407, national board# 3594, built 2007.

-

Used 200 liter Pure-Flo Precision reactor, 316L stainless steel construction, removable dish top, dish bottom, rated 50 psi and full vacuum at 400 f internal, jacketed for 90 psi and full vacuum at 400 f, bottom mounted agitator drive, on legs, serial# 221366-4, national board# 10201, built 2003.

-

Used 50 gallon Allegheny Bradford reactor, stainless steel construction, removable dish top, dish bottom, rated 150 psi and full vacuum at 200 f internal, jacketed for 70 psi at 200 f, top mounted off set agitator drive, on legs, serial# 5534-3-4-2, national board# 1498, built 2000.

-

Used 200 liter Precision Stainless reactor, 316L stainless steel construction, dish top, dish bottom, rated 45 psi and full vacuum at 400 f internal, jacketed for 90 psi at 400 f, bottom agitator drive, on legs, serial# 4169-2, national board# 7117, built 1997.

-

Unused Sartorius single-use mixer, 650-liter capacity, serial# MC4349.

-

GE Healthcare bioreactor, model XDR-200. Includes (2) Rosemount Analytical model 1056 dual channel intelligent transmitters and (4) peristaltic pump heads, serial# 29117981, with GE Healthcare X-Station touchscreen bioreactor workstation, model X-Station, serial# 29117981, built 2014.

-

Unused Cytiva bioreactor system, model XDR-500. Includes workstation controller and temperature control chiller unit, serial# 29708712.

-

Unused PALL Life Sciences bioreactor vessel, model iCELLis 500+, part# 4415-I500V500.

-

Unused Caron CO2 incubator with touchscreen display controller, model 7401-33-1, R134A refrigerant, 115V, 60 Hz, serial# 7401-33-1-277, with Unused Caron Products condensate recirculating system, model CRSY-102-1. Water purity (measured internally): 100 to 125 K Ω/cm, water reservoir: 7 gallons (26.5 liters), serial# CRSY102-1-1240.

-

Used Cytiva XDR-500 bioreactor system, model XDR-500. Includes (2) Rosemount Analytical model 1056 dual channel intelligent transmitters and (4) peristaltic pump heads, serial# 29294331, built 2018.

-

Used GE Healthcare bioreactor, model XDR-200. Includes (2) Rosemount Analytical model 1056 dual channel intelligent transmitters and (4) peristaltic pump heads, serial# 29117980, built 2014.

-

Cytiva AKTAprocess chromatography system, model 28964323. Includes (2) 1 hp 3-head pumps and (2) Ice Qube Inc. model IQ300FPW wash down filter fans, serial# 28964323, built 2009.

-

Used Cytiva Xcellerex single-use mixing system on 4-load cells, model XDUO 2500 SS, thermal jacketed with Siemens model Simatic HMI touch screen controller, Rosemount Analytical model 1056 dual channel intelligent transmitters, and (2) peristaltic pump heads, serial# 29609911, built 2020.

-

100 liter GE single-use mixer, model XDUO-100-T on (4) load cells. Includes Lenze variable speed controller, (2) pump heads, and Emerson model 1056 controller, serial# 29142975, built 2015.

-

GE Wave 25 rocker bioreactor system. Includes (2) part# 29032003 ReadyToProcess Pump 25, part# 29044081 ReadyToProcess CBCU full controller, and Dell Optiplex 9020 computer system, serial# 1825652.

-

Molecular Devices multi-mode microplate reader, model SpectraMAX i3, serial# 35-370-1562.

-

Sartorius Stedim stirred single-use bioreactor touchscreen controller, model BIOSTAT CultiBag STR Plus. Includes (3) peristaltic heads, capacity up to 1,000 liters, serial# 00196/10.

-

GE automated liquid chromatography system, model AKTAprocess. Includes (2) 1 hp 3-head pumps and Ice Qube Inc.model IQ300FPW wash down filter fans, serial# 28954841, built 2009.

-

Sartorius single-use jacketed bioreactor, model BIOSTAT Cultibag STR 200-DW. Includes Watson Marlow model 323 digital peristaltic pump, load cells with Sartorius model Midrics 1 display terminal, serial# STR 0584, built 2016, with Sartorius Stedim single-use bioreactor touchscreen controller, model BIOSTAT CultiBag STR Plus. (8) peristaltic heads, serial# 00688/16.

-

Unused GE single-use bioreactor, model XDR-50 on (3) Mettler Toledo load cells and model M400 multi-parameter process transmitter. Includes (2) Rosemount Analytical model 1056 dual channel intelligent transmitters, (4) peristaltic pump heads, and mobile touch screen control workstation, serial# XDR-8561-05-001 with GE Xcellerex bioreactor operator interface terminal, model XDR-OIT. Includes Strongarm touch screen control, serial# OIT-8561-05-001, built 2012.

-

Mobile pump system with touchscreen controller and Endress + Hauser model RSG40 memograph, Cole-Parmer model 875-2614 digital 0.5 hp MasterFlex B/T peristaltic pump.

-

Thermo Scientific large-capacity reach-in CO2 incubator, model 3950, ambient +5 to 60 deg C, 29 cu.ft., serial# 49341-382. Note: front glass door needs replacement.

-

Unused Sartorius single-use mixer, 1,000-liter capacity, serial# MC4609.

-

Unused Sartorius single-use mixer, 650-liter capacity, serial# MC4613.

-

1,000 liter Thermo Fisher Scientific single-use mixer with SEW-Eurodrive 5 hp mix motor on (3) Mettler Toledo load cells, part# IM1918, serial# H18378-01, built 2019.

-

Unused Cytiva BPG 200/500 glass chromatography column, model 18110311, with part# 18103120 mobile column stand.

-

Used 50 liter Pope bioreactor, 316L stainless steel construction, approximately 16" diameter x 18" straight side, removable dish top, dish bottom, rated 100 psi and full vacuum at 350 f internal, jacketed for 100 psi at 350 f, top mounted .25 DC agitator drive, (4) baffles, mounted on cart with lift lift assist, serial# 140243-4-1, built 2006.

-

Unused 500 liter Mueller bioreactor, 316 stainless steel construction, approximately 32" diameter x 38" straight side, dish top and bottom, rated 45 psi at 300 f internal, jacketed for 100 psi at 300 f, top entering off center Lightnin agitator drive, model X5S33, serial# 391517, national board# 45429, built 2008.

-

Used Beckman Avanti 30 refrigerated centrifuge, 30,000 RPM, 208 volt, serial# CGE98C08.

-

Used Beckman Coulter Access Immunoassay System, model Unicel DxI 600, up to 200 tests per hour throughput with up to 60 onboard samples, made in 2016, Ref # A30260, with PC and Powervar Security Plus UPS.

-

Used Watson Marlow peristaltic pump, model 701S/R, 360 rpm, serial# 130797.

-

Used 500 liter Thermo Scientific imPULSE single use mixer, part# IM00500.6033, stainless steel construction, 500 liter stainless steel bag holding vessel, full hinged side access door with window, jacketed vessel rated 150 psi at 150 f, certified by Cone Craft, serial# H20346-01, national board# 1458, bottom mounted reciprocating mixer drive, side mounted control system with Allen Bradley PanelView Plus touchscreen controller and plc controllers, on stainless steel frame with load, system serial# H20346-01, built 2021.

-

Used Agilent 1260 Infinity II HPLC System consisting of 1X1260 Isocratic Pump (ISO) serial# DEAEH01141 1X 1200 Analytical Light Scattering (ALS) serial# DE64764961 1X1260 Multicolumn Thermostat (MCT) serial# DEAED10460 1X 1100 Refractive Index Detector (RID) serial# DE43801720.

-

Used Perkin Elmer Paragon 1000 PC FT-IR Spectrometer, benchtop design, serial# 38716.

-

Used Millipore QuickScale 53cm Chromatography Column, serial# QW450-0059, built 2006.

-

Used Shimadzu HPLC System, consisting of CTO-10A Column Oven, DGU-14A Degasser, SCL-10A System controller and two LC-10AD Liquid Chromatographs.

-

Used 48" Walker Transfer Isolator, 316L stainless steel construction, 48" long x 24" wide x 30" high chamber, (2) glove ports, setup for vaporous hydrogen peroxide sterilization, with HEPA filtration and light, 120 volts, serial# BS-30013-1, built 1998.

-

Unused Howorth isolator, 316L stainless steel construction, approximately 9'6" long x 24" deep x 36" high inside chamber, single sided, 6 gloves with side access door, (2) 16" X 29" side access doors, 18" bottom outlet with cover, 4" bottom outlet with cover, CIP spray balls, (2) top mounted internal lights, 1 hp, 230/460 volt blower, on stainless steel stands with control panel, serial# 4344-200, new 2009.

-

Used 54" Flow Science vented safety enclosure, model FS2500-17BKDVA, serial# 12-N-15-01.

-

Used Malvern Nano-Z Zetasizer particle size analyzer, model ZEN2600, serial# MAL1224555, built 10/2019.

-

Used Nova Biomedical cell culture analyzer, model pHOx, serial# T07607151.

-

Used Millipore Milli-Q Gradient A10 Water Purification System.

-

Used 1,000 Liter Xcellerex single use bioreactor, model XDR-1000, stainless steel jacketed housing, jacket rated 100 psi at 150 f, bottom mounted agitator drive, project# 8968, serial# 19138, built 2010.

-

Used 53 gallon (200 liter) Eagle Stainless tank, 316 stainless steel construction, model CTH-565-H, approximately 22" diameter x 35" straight side, open top with lid, flat bottom, (1) 4", (1) 2", (5) 1.5" nozzles on lid, on wheeled caddy, serial# 100946.

-

Used 250 gallon Befco reactor, stainless steel construction, approximately 42" diameter x 42" straight side, dish lid top with dish bottom (no lifting piston), internal rated 100 psi at 300F, jacket rated 75 psi and full vacuum at 250 F, (2) 4", (3) 2", and (1) .75" nozzles on top, 3" center bottom outlet, on wheels, serial# B10-1259, national board# 287, built 2010.

-

Used 79 gallon (300 liter) Inox reactor, stainless steel construction, approximately 24" diameter x 34" straight side, dish lid top with dish bottom, jacket and interior rated 30 psi and full vacuum at 300 F, 6" top access, with (1) 4", (1) 3", (2) 2" and (2) 1.5" nozzles on top, with bottom entering magnetic agitator, .75 hp with controls, 1.5" center bottom outlet, with load cells, all on portable frame, serial# 95011-2, CRN# K82555, built 1995.

-

Used Agilent gas chromatograph, model 6890A, serial# US00034267 with Agilent 7683 series injector and Hewlett Packard HP 7694 headspace sampler.

-

Federal Equipment Company sells biopharma bioreactors used for biochemically active reactions. Our inventory features bench-top fermenters and bioreactors for use in research and development through pilot and scale-up fermentation systems and all the way up to commercial production bioreactors. These fermenters and bioreactors are commonly made from stainless steel or glass. We offer used fermenters and bioreactors made by the top manufacturers like B. Braun, Applikon, Cytiva, ABEC, Thermo Fisher Scientific, Sartorius, Precision, New Brunswick, Pierre Guerin and many others.

-

Eppendorf New Brunswick BioFlo/CelliGen 115 Fermenter Bioreactor, 120 volt, serial# B115FI804092.

-

Used 10 liter New Brunswick fermenter, model BioFlo 3000, 316 stainless steel construction, 8.5" diameter x 14" straight side, flat bolt on top, dish bottom, 14 liter total capacity, 10 liter max working capacity, 3 liter min working capacity, temperature range from 5 C above coolant temp to 80 C, +/- .1 C or +4 C to 80 C, Magmotor agitator drive with two tier six blade paddle agitator, sparger ring, harvest tube, RTD sensor tube, provision for pH and DO monitoring, top mounted jacketed dust filter, 4 baffles, bottom stainless steel water jacket, (5) peristaltic pumps with PLC controls, 120 volt, mfg# m1227-1013, serial# 000787979, built 2000

-

Used 80 liter Pierre Guerin Bioreactor, project# H1M6020, 80 liter working capacity, 128 liter total capacity, " diameter x " straight side, flat bolt on top, dish bottom, rated 4 bar(58 psi)/- 1 bar(-14.5 psi) at 150° c (302° f) internal, rated 6 bar (87 psi) at 150° c (302° f), top mounted 0.25 kw agitator drive, skid mounted packaged system with monitoring system, mass flow meter, filter housing, pump and valving, vessel mfg# H1M602110-2, built 2006.

-

Used 200 liter Sartorius Stedim BioSTAT CultiBag single-bag-use Bioreactor, model STR-200-DW, stainless steel housing, jacketed for 2 bar at -10/+5- c, top mounted servomotor agitator drive, project# BB-8804079, serial# STR-0034, built 2009.

-

Used 200 liter (52 gallon) ABEC fermenter system, 316L stainless steel construction, approximately 24" diameter x 39" straight side, hinged dish top, dish bottom, baffles, rated 40 psi and full vacuum at 400° f internal, jacketed for 60 psi and full vacuum at 400° f, bottom entering agitator drive with, 3 hp, 208-230 volt motor with two tier 6 blade agitator, skid mounted controls, with vfd for agitator, vessel certified by Precision Stainless, serial# 6240, national board# 1267, built 1985.

-

Used 200 liter Sartorius Stedim BioSTAT CultiBag single-bag-use Bioreactor, model STR-200-DW, stainless steel housing, jacketed for 2 bar at -10/+5- c, top mounted servomotor agitator drive, project# BB-8804079, serial# STR-0034, built 2009.

-

Used 300 sq ft BOC Edward freeze dryer, model LYOMAX 28, 316L stainless steel product contact surfaces with (13) 1170 mm wide x 1850 mm deep usable shelves, 115 mm shelf spacing, stoppering, external condensor with 300 kg ice capacity, refrigeration and vacuum skid with liquid natural gas refrigeration, model AV-LUS BOC Edward loading / unloading skid, 480 volt with controls, freeze dryer serial# MTE1930, built 2004.

-

Used Dorr-Oliver High Pressure Liquid Chromatograph (HPLC), Model XP Prep 15LPM, explosion proof design, Class 1 Div. 1, Group D with pumps and columns, 230 volt.

FEATURED USED EQUIPMENT

-

Used GEA Mobile Minor Spray Dryer, Model MM-PSR, stainless steel construction, 0.8 meter diameter chamber, GEA Niro nozzle atomixer, cone bottom, with top expansion chamber, with inlet HEPA filter housing, cyclone fines collector, discharge filter housing, and .95 kw blower, control panel with Allen Bradley Panelview1500 HMI, project# 1093-2412, built 2017.

-

Brand new BMT Steripro cGMP steam sterilizer, model SPV9612-2AGV. The Steripro SPV9612-2AGV is a high-performance steam sterilizer designed for pharmaceutical and biotech production environments where repeatability is critical. Featuring a polished 316L stainless steel chamber and sanitary piping, it ensures durability and compliance with cGMP standards. Equipped with industrial-grade PLC control systems and high-grade vacuum pumps, it delivers precise and repeatable sterilization cycles with temperature uniformity better than ±0.5°C. Serial# AC22053, built 2022. The unit is already packaged, and installation is included with the sale for seamless setup and operation.

-

Brand new Lytzen depyrogenation oven, model LDF-380. The Lytzen LDF-380 is a high-performance depyrogenation oven designed for ISO Class 5 (formerly Class 100) cleanliness throughout the cycle. With a fully welded stainless steel chamber, it operates at up to 280°C for effective pyrogen removal. Its forced air convection system ensures uniform heat distribution, while a semi-automatic flush door enhances ease of use. Serial# A20221074, built 2022. The unit is already packaged, and installation is included with the sale for seamless setup and operation.

-

Used Pharma Packaging System bottle filling line consisting of: - Accumulation feed table, stainless steel construction. -Pharma Packaging Systems lane counter, model 8-1 Vitacount, (8) lane, stainless steel product contact surfaces, single filling station, with reject, with HMI touch screen, 230 volt, 50 Hz, serial# PPS 544, built 2013. -Accumlation discharge table, stainless steel construction, -Domino A420i coder, serial# AST00117225, -Enercon induction sealer, model Super Seal.

-

Used Freund-Vector TFC-220 Pilot Scale Roll Compactor/Granulator, stainless steel construction, 20g - 20kg/hour capacity, with 200mm diameter x 20mm roll face rolls, grooved rolls, product hopper with integrated tapers de-aeration screw, with bottom mill, operator HMI touch screen, 230 volt, serial# RC-330, built 2012.

-

Used Stokes BB2 Tablet Press, 45 station, B-tooled, dual sided, 4 ton compression, feed frames with hoppers, 7/16" max tablet diameter, 11/16" max depth of fill, 4200 tablets per minute max speed.

-

Used 600 Liter Pfaudler receiver tank, 316L stainless steel glass lined body, 316L stainless steel removal dish top, rated 50 psi and full vacuum at 450 f internal, on stand, 4015 glass steel lining, Feldmeier top part# SO33612B, serial# J093372, national board# 52545, built 2012.

-

Used 50 Liter Diosna high shear mixer, Model P50, stainless steel construction, jacketed bowl, 3 kw mixing blade motor drive, side plug valve discharge, Allen Bradley PLC controls with Panelview HMI touchscreen, 460 volt, serial# 240 049.

-

Used Glatt GPCG2 LabSystem Fluid Bed Dryer, 200-460V, 50/60Hz, 3 PH, serial# 79589, built 2013.

-

Used Vector Freund roller compactor system, model TFC-LABO, stainless steel construction, approximately 50 mm roll diameter x 24 mm roll face width rolls, vertical compression screw with motor, with motor controllers for rolls and feed screw, rated 5 g-1 kg/hour production speed, with Vector oscillating granulator, serial# RC-266 46483, built 2008.

-

Used Brabender Twin Screw Feeder, Model DDW-MD0-MT-0-ISC, stainless steel construction, 25-120 g/hour rating, CE design, serial# 1700795.0578, built 2017.

-

Used 4.6 Sq Ft SP Scientific freeze dryer lyophilizer, model LyoStar 3, part# 100011095, stainless steel product contact surfaces, with (3) approximately 11" wide x 20" deep usable shelves, 2.8" shelf spacing, bottom up stoppering, 30 liter max condenser capacity, R-404a and R508a refrigerant, 230 volts, 5659 meter hours, serial# 321348.

-

Used 1500 liter DCI reactor, 316 stainless steel construction, approximately 50” diameter x 45” straight side, dish top and bottom, rated 45 psi and full vacuum at 250 f internal, jacketed for 145 psi and full vacuum at 364 f, top entering off center 1 hp agitator with mechanical seal, 18” top manway, on legs, serial# JS3464, national board# 6432, built 2006.

-

Used 60" O'Hara FastCoat coating pan, model FC400 (60xc5), stainless steel construction with 60" diameter perforated Pan, solvent rated design, O'Hara advanced controls with Allen Bradley Compact Logix PLC, PC and HMI units, O'Hara manifold with Schlick nozzle spray arm, built in Watson Marlow peristaltic pump with Micromotion mass flow and recirculation system, reverse pan unloading, outdoor rated air handling unit (AHU) with preheat steam coil, chilled water dehumidification unit, steam reheat with face/bypass temp control dampers, HEPA module, Camfil DCU with FIKE suppression and isolation system, bag in bag out with exhaust HEPF module, 480 volt, system serial# 4501, built 2020.

-

Used GEA Mobile Minor Spray Dryer, Model MM-PSR, stainless steel construction, 0.8 meter diameter chamber, GEA Niro spray nozzle atomizer, cone bottom, with top expansion chamber, cyclone fines collector, discharge filter housing, with control panel, serial# 3332, built 2009. Unit requires blower.

-

Used GEA Mobile Minor Spray Dryer, Model MM-PSR, stainless steel construction, 0.8 meter diameter chamber, GEA Niro nozzle atomixer, cone bottom, with top expansion chamber, with inlet HEPA filter housing, cyclone fines collector, discharge filter housing, and .95 kw blower, control panel with Allen Bradley Panelview1500 HMI, project# 1093-2412, built 2017.

-

Used IMA cotton inserter, model 150, single head, with integrated conveyor, fallen bottle and tablet reject stations, air bottle reject, with Allen Bradley PLC controls, 208 volt, serial# 254, built 2015.

-

Unused Fluid Air 300 liter fluid bed dryer, model 300, 316 stainless steel contact parts, 304 non product contact, includes tower, filter system, explosion suppression system, product bowl with automatic side discharge, hydraulic bowl lifting system, spray nozzles (for possible conversion to top spray granulation), HMI and machine controls, valves, and other associated parts, serial# 10440, built 2014.

-

Used Fitzpatrick Chilsonator roller compactor, model 1.5LX8D, with 8" diameter x 1.5" wide grooved rolls, vertical and horizontal pre-compression screws, serial# 489.

-

Used 16 quart Patterson Kelly twin shell Blendmaster blender, 1 6 quart stainless steel shell, rated 200#/cu ft max material density, serial# C419381.

-

Used GlobePharma rotary tablet press, type Versapress, model Versa-II10BD, 10 station turret with (5) D and (5) B stations, keyed upper punch guides, 3 hp, 220 volt, serial# F0418021/34873m built 2018.

-

Used Buchi mini spray dryer, model B-290, with glass chamber and cyclone fines collector, electrically heated, 2900 watt heater, 230 volt, serial# 0600000592.

-

Used ACG capsule filler, model AF TLab, speeds from 6000-25000 capsules/hour, 220 volt, CE design, batch# 2522/10/01, serial# 102, built 2020. includes ACG capsule polisher unit, model DP100, batch# DP62/30/21, serial# 2664, built 2020 and ACG empty capsule sorter, model ECS 100, batch# EC60/30/03, serial# 2098, built 2020.

-

Used ThermoScientific Haake Pelletizing line, with model Phama 11 HME twin screw extruder, item# 553-0020, co-rotating screws, 40:1 l/d, 1000 rpm screw speed, 1.5 kw motor drive, with feeder, and operator HMI touchscreen. ThermoScientific Ph11 Conveyor, item# 553-0600, serial# 1-21004125001. ThermoScientific pelletizer, 6 blade rotor with pull roll, 230 volt, CE design, extruder machine# KU18-000011, serial# 1-1800319001, built 2019.

-

Used A Berents BECOMIX planetary mixer, model RW 30, stainless steel construction, 60 liter total capacity, 30 liter working capacity, chamber rated -1/2 bar(-14.5/29 psi) at 134 c internal, jacketed for 4 bar(58 psi) at 152 c, top mounted variable speed agitator with side wall scrappers, bottom mounted homogenzier, dome top with lift/lower mechanism, cone bottom, with on board controls and external control panel, 3/50/400 volt, Fabr# 011/1-586, built 1996.

-

Used ThermoScientific Haake Pelletizing line, with model Phama 11 HME twin screw extruder, item# 553-0020, co-rotating screws, 40:1 l/d, 1000 rpm screw speed, 1.5 kw motor drive, with feeder, and operator HMI touchscreen. ThermoScientific Ph11 Conveyor, item# 553-0600, serial# 1-21004125001. ThermoScientific pelletizer, 6 blade rotor with pull roll, 230 volt, CE design, extruder machine# KU18-000011, serial# 1-1800319001, built 2019.

-

Used Silverson high shear mixer, model HSM100CIT, stainless steel mixing head, bench top design.

-

Used Globepharma tablet deduster, model GPTD-100, 115 volt, serial# 011934876, built 2019.

-

Used Buchi mini spray dryer, model B-290, with glass chamber and cyclone fines collector, electrically heated, 2900 watt heater, 230 volt, serial# 0600000592.

-

Used O'Hara LabCoat bench-top coating pan, model LABCOAT BT, stainless steel product contact surfaces, with 8.5" perforated pan with plenum, spray guns with Watson Marlow peristaltic pump system, on board air handling system, electrically heated, Siemens controls, 220 volt, 1 phase, 60 hertz, serial# 414, built 2015.

-

Used Filamatic piston filler, model DAB-32-4, with (2) fill heads with pumps, on stand, 220 volt, serial# 022942.

-

Used MGS horizontal continuous motion cartoner, model Stealth, with powered carton magazine, feed belt, glue closure with Nordon gluer, PLc controls with HMI screen, kick reject station, 230 volt, serial# 12726, built 2008.

-

Used MGS case packer, model Advantage with powered case feeder, dual tag heads, PLC controls with HMI, 230 volt, serial# 12727, built 2008.

-

Used VWR ULT freezer, model 5706, capable of -80 C temperatures, R-404a, R-508b refrigerant, 2 stage operation, with chart recorder and controls, (4) shelves, 208/230 volts, serial# 833437-852, built 2013.

-

Used Shimadzu X-Ray Diffractometer, model XRD-6000, 220 volt, serial# Q30344800678 CZ

-

Unused Mettler Toledo Checkweigher, model C3570 Advancedline, 800 gram weight range, left to right configuration, kick reject, 240 volt, with him screen, serial# C118690762, built 2021.

-

Applied Biosystems genetic analyzer, model 3500, integrated autosampler, 120 volts, serial# 24158-161.

-

Used Littleford mixer, model FM-130-D, stainless steel construction, 4.6 cu ft total capacity, 2.8 cu ft working capacity, 10 HP 230/460 volt main drive, plugged chopper opening, no mount, air purge seals, manually operated flush type discharge, on stand, serial# 43608-5972, built 2011.

-

Used Mettler Toledo Safeline metalcheck, model 2S, CE rated, 240 volt, serial# 121323, built 2014.

-

Used Vector fluid bed flow coater dryer, model FL-M-15, stainless steel construction, with 9" wurster insert, top spray insert with 45 liter product bowl, top spray insert with 20 liter product bowl, on carts, system is less controls, air handling and blower, serial# FL-299 45018, built 2001.

-

Used IKA process lab mill, model Magiclab, 900 watt motor, 240 volt, serial# U078310.

-

IKA Process Pilot mill, type UTL2000/4, model P011036, stainless steel construction, 3 hp drive, 208-230/460 volt, 3 phase, serial# 1769.

-

Used Carl Zeiss Microscope, with AxioCam MRc5 and H.I.P controls, CE design, serial# 39180008000.

-

Used Erweka Erweka All Purpose System, Model AR 402, with multiple attachments, including Coating Pan, Dual Roll Crusher and Y Tumble Blender.

-

Used Glatt Roto-granulation bowl insert, stainlesss teel construction, approximately 25" inner diameter x 12" deep bowl, with rotary plate, with bowl cart, serial# 6617.

-

New and Unused BAUSCH Advanced Technology Group (BATG) vial filling line.

-

Used Nikka Densok pinhole inspector, model HDB-204V-AS+DL, currently with 2ml change parts, with controls and control computer, with reject, serial# 490, built 2005.

-

Used Mettler-Toledo Hi-Speed checkweigher, model CS3400GT-MM, with controls, serial# 14030.

-

Used Precision Scientific mechanical convention incubator, model 30M, stainless steel interior, 30" x 24" x 73" high chamber, rated up to 65 C, 1450 watt, 120 volts, serial# 9212-001.

-

Used Optel label vision inspection system, model OP300, with label printer and handheld scanner, mounted on stainless steel table, 120 volts, system serial# OP6354-09.

-

Used Optel visual inspection system, model OP300, with mounted camera and touchscreen interface, mounted on stainless steel table, 120 volts, serial# OP6354-02.

-

Used 10 sq meter (107 sq ft) Telstar Freeze Dryer, model Lyomega 100GN2, stainless steel construction, front loading/unloading with access door, with (10) 90 cm wide x 120 cm deep usable shelves, (11) total shelves, external condensor, stoppering with top mounted hydraulic ran with pump, refrigeration and vacuum skid with Cumulus PX20 refrigeration package, (2) 2.2 kw Telstar vacuum pumps with (1) 1.7 kw Aerzen booster pump, integrated control panel with Allen Bradley SLC 5/05 PLC controller, and external hmi control, serial# 231796. Built 2006.

-

Used 300 sq ft BOC Edward freeze dryer, model LYOMAX 28, 316L stainless steel product contact surfaces with (13) 1170 mm wide x 1850 mm deep usable shelves, 115 mm shelf spacing, stoppering, external condenser with 300 kg ice capacity, refrigeration and vacuum skid with liquid natural gas refrigeration, model AV-LUS BOC Edward loading / unloading skid, 480 volt with controls, freeze dryer serial# MTE1930, built 2004.

-

Used 12.26 sq meter (131.91 sq ft) BOC IMA freeze dryer, model LyoMax12, 316L stainless steel product contact surfaces, wth (12) total, (11) usable shelves, 914mm x 1219MM x 15mm thick shelves, 145mm shelf spacing, top down stoppering, rated to -60 c min temperature, slotted doors with unloading system, 17 sq meter external condensor, 345 kg ice capacity, (3) 30 hp Mycom refrigeration compressors, (2) EH250 Edwards vacuum pumps, SIP/CIP capable, Allen Bradley controls, 480 volt, serial# FD2889, built 1996.

-

Used 4.6 Sq Ft FTS Systems- SP Scientific freeze dryer Lyophilizer, model LyoStar 3, part# 100005824, with Praxair ControLyo nucleation on demand technology, stainless steel construction, with (3) approximately 11" wide x 20" deep usable shelves, 2.8" shelf spacing, -70/+60 c temperature range, 850 sq inch external condenser rated to -85 c, 30 liter ice capacity, bottom up shelf stoppering, integrated Oerlikon Trivac vacuum pump, refrigeration system with dual compressors, R404A and R508B refrigerant, 230 volt, 1007.7 run hours, serial# 320588.

-

ProSys S06428 Containment and Sampling Technology is a single-chamber closed-barrier system providing protection from cross-contamination between a process and the surrounding laboratory. The Isolator is rated ISO5. (International Standards Organization) (for particle count) environment in operation.

-

Used Glatt CPS 3 Fluid Bed Dryer, model CPS 3 Lab System, Roto-granulator chamber, made in 2011, S/N 11565.

-

Used Capmatic semi automatic piston filler, model CF-2P, 220 volt, bench top design, serial# 2P08031487, built 2008.

-

Used 10 cu ft Patterson Kelly twin shell blender, stainless steel construction, rated 62#/cu ft maximum material density, provision for high speed intensifier bar(less car and capped off) with 5 hp motor, shell driven by 1 hp, 230/460 volt motor drive, on stand, serial# 301460. Missing cover, cover tie down bars and bottom outlet valve.

-

Used Fitzpatrick Fitzmill, model D6A, stainless steel construction, pan feed, driven by 5 HP, 230/460 volt motor, on stand, serial# 10770.

-

Used Fortress Technology Phantom Metal Check Detector on Mobile Stand. Asset# EN 200240.

-

Used Cozzoli powder filler, model PF2-IS-176, stainless steel construction, incomplete unit, Allen-Bradley PLC with touchscreen interface, 115 volts, portable on casters, built 2019. As Is.

-

Used Sensum tablet inspection machine, model SPINE, designed for inspection of complete surface of tablets, including engraving, speeds up to 360,000 tablets/hour for round and oblong plain tablets, 240,000/hour for engraved round tablets, 300,000 tablets/hour for oblong engraved tablets, with stainless steel product hopper and integrated operator HMI, 230 volt, 60 hertz, CE design, serial# 073, built 2017.

-

Used 10 gallon Ross planetary mixer, model PVM10, stainless steel construction, vacuum cover, anchor agitator with bottom and sidewall scrappers Teflon lined, driven by 3 hp mechanical variable speed motor, high speed disperser driven by 5 hp mechanical variable speed motor, and mixer emulsifier with Teflon lined rotor stator head, driven by 1.5 hp motor, all motors XP rated, 230/460 volt, (1) stainless steel jacketed mix can, (1) stainless steel Teflon lined jacketed mix can, air over oil hydraulic lift with air tank, jacketed mixing can, on base, serial# 50365.

-

Used Cu ft Matcon IBC bin, stainless steel construction, approximately 43" x 43" x 15" straight side x 27" deep cone bottom, fork access and stackable, serial# 2298.

-

Used Epsilon Pharmaservices Mixing Tank, 135 Litre Capacity, 316 SS, Propellor agitator, made in 2015, S/N C1103-01.

-

Used Glatt CPS 3 Fluid Bed Dryer, model CPS 3 Lab System, Roto-granulator chamber, made in 2011, S/N 11565.

-

Used Buchi Mini Spray Dryer, model B-290, with glassware and nozzle atomizer, 230 volt, CE design, serial# 1100006095, built 2019.

-

ProSys S06428 Containment and Sampling Technology is a single-chamber closed-barrier system providing protection from cross-contamination between a process and the surrounding laboratory. The Isolator is rated ISO5. (International Standards Organization) (for particle count) environment in operation. An integration with a bio-decontamination system allows parametric surface bio-decontamination and their ventilation systems, prior and after processes.

-

Used L.B. Bohle LM40 laboratory bin blender drive unit, model LM40, stainless steel construction, 40 kg safe load capacity, 110/230 volt, .32 kw rated power, serial# 9906995001, built 2000. Less bins and bin holder.

-

IMA Precisa 18 High Speed Tablet/Capsule Checkweigher, serial# PA1114.

-

IMA Precisa 18 High Speed Tablet/Capsule Checkweigher, serial# PA1114.

-

Used Fette Checkmaster 4.1 Tablet Tester, 230 volt, serial# 82 1342, built 2005.

-

Used Quadro Comil , model U5, stainless steel construction, on adjustable stand, serial# U5-0290, built 2010. Requires blade and screen.

-

Used 150 liter Mueller reactor, 316L stainless steel construction, approximately 26“ diameter x 20” straight side, dish top and bottom, rated 35 psi and full vacuum at 284 f internal, jacketed for 60 psi and full vacuum at 284 f, off center top entering .5 hp agitator drive, on legs, serial# P29282-1, national board# 14718, built 1989.

-

Used Quadro Comil, model 194S, stainless steel construction, with beater, 5 hp, 230/460 volt xp variable speed motor on stand, serial# 194-1217, built 2001.

-

Used 200 mm Cassel flow thru metal detector, type Shark 2A GF0200. 200 mm diameter aperture, with stainless steel reject system, and digital readout, serial# D180288.03G, built 2018.

-

Used 8/4 quart Patterson Kelley Blend Master twin shell blender, with 8 quart and 4 quart stainless steel shells, 125/140#/cu ft max material density, provision for liquid solids bars(does not include bars) with motor drives, serial# C424817.

-

Used 25 liter TK Fielder high shear mixer, model PMA 25/2G, stainless steel construction, 5.5 kw, mixer motor drive, with chopper(less blade), side plug valve discharge, with external control panel, serial# 2553, built 1985. As Is.

-

Used Diosna P1/6 High Shear Granulator. S/N: 355-152

-

Used Filamatic Filler, Model AB-5, with fill piston and filling nozzle, 110 volt, serial# 022578.

-

Used Vector Lab High Shear Mixer, Model GMX-Lab Micro, stainless steel construction, with 4 liter and 1 liter jacketed bowls, Allen Bradly controls with MMI, 220 volt, serial# GMX-162 46117, serial# 2007.

-

Used 25 Liter Vector high shear mixer, model GMX 25, stainless steel construction, 25 liter jacketed bowl, Allen Bradley controls with HMI, 230 volt, serial# GMX-185 48181, built 2007.

-

Used ProCepT R&D spray dryer system, type 4M8-TriX, stainless steel chamber holder, modular design, with VWR temperature control unit, dosing pump, scale, air filtration system, with controls, on portable frames, 230 volts, serial# 0111-4M8Trix-16, built 2016. As is.

-

Used 59" Terra Universal glovebox, plastic construction, approximately 59" long x 23" deep x 24" high chamber with (4) glove ports, with integrated nitrogen purge system (external nitrogen required), side access, with approximately 10" x 11" x 10" antechamber, portable on table, serial# 168505.

-

Used Food Pharma Systems (FPS) micronisation mill, model PilotMill Zero, stainless steel construction, pneumatically operated with 6 barg max working pressure, with carrying case, serial# FPS0737A, built 2016.

-

Used Sepha deblistering machine, model PRESSOUT, manual operation, with (3) size plates, serial# 411-212, built 2017.

-

Unused LB Bohle bin blender, model LM40.

-

Used Syntegon high speed capsule filler, model KKE 1700, speeds up to 103,200 capsules/hour, 758541, built 2022.

-

Used Alfa Laval / Bran+Luebee homogenizer pump, model SHL 15, stainless steel product contact surfaces, serial# 59-10361, built 1985.

-

Used Alfa laval disc centrifuge clarifier, model VNPX 510 SGD 34 GS, stainless bowl, 6235 rpm max bowl speed, 22 kw motor, with onboard controls, serial# 4 088 623, built 1996.

-

Used GlobePharma MiniBlend twin shell blender, model MNB-1 with 2 quart, 1 quart, and 0.5 quart stainless steel shells, t V-Cones, .1 hp 110 volt motor, serial# 12098879.

-

Used Microfluidics Microfluidizer, Model LM10, stainless chamber, nominally rated up to 23000 psi, pneumatically operated, 30 mL sample side, up to 600 mL flow rate, with touch screen, serial# LM10-0237, built 2019.

-

Used Hendriks Lyosphere, Model Bollomaat generation 1, for Lyobead production, (4) head with Flexicon pump cart, Demaco cyrogenic system, serial# 34500-001, built 2010.

-

Used 200 liter Holloway America bioreactor, 316L stainless steel construction, hinged dish top, cone bottom, rated 43 psi and full vacuum at 302 f, jacketed for 145 psi and full vacuum at 302 f, bottom mounted Nord agitator with .5 hp motor drive, on legs, serial# B10448, national board# 2464, built 2017.

-

Used 1250 liter ABEC fermenter reactor, 316L stainless steel construction, approximately 42" diameter x 63" straight side, dish top and bottom, rated 45 psi and full vacuum at 350 f internal, jacketed for 150 psi and full vacuum at 350 f, bottom mounted agitator drive, on 3 legs, serial# PJS001925, national board# 1696, built 2018.

-

Used 500 liter Thermo Scientific imPULSE single use mixer, part# IM00500.6033, stainless steel construction, 500 liter stainless steel bag holding vessel, full hinged side access door with window, jacketed vessel rated 150 psi at 150 f, certified by Cone Craft, serial# H20346-01, national board# 1458, bottom mounted reciprocating mixer drive, side mounted control system with Allen Bradley PanelView Plus touchscreen controller and plc controllers, on stainless steel frame with load, system serial# H20346-01, built 2021.

-

Used 300 liter ThermoScientific Single Use Fermenter, type 300L HyPerforma, part# SUF0300.6232, with Hyperform G3 Lite Controller, stainless steel jacketed bag support container, jacketed for 150 psi at 150 f, with hinged bioprocess container door, certified by Anderson Dahlen, serial# ADIAT10, national board# 1278, built 2020, top mounted 2 hp agitator drive, external condensor, Thermo Scientific serial# AD33332, built January 2021.

-

Used Eppendorf New Brunswick CelliGen BLU Bioreactor, Single Use Vessel/Stirred Tank Bioreactor, Uses Consumable Hard Plastic Reactor vessels with Integrated Agitators, Servo Agitator Drives are Part of Main Controller, with Integrated Peristaltic Pumps, 120v, S/N BBLUCG701671

-

Used Capmatic inline vial filling line, model Conquest FS8 consisting of: 36" Capmatic accumulation table, serial# TT01110917: Model Conquest FS8 Capmatic inline filler, (16) head walking beam filling station with (8) piston fill pumps, integrated chain conveyor and rotary stopper feed system with vibrating bowl feeder, Allen Bradly Panelview 1000 HMI, serial# CQ1110919, built 2002: Model R-R Pharma Capmatic crimp capper, type RoadRunner, (12) station with Capmatic cap elevator, Allen Bradley PLC controls and Panelveiw 900 HMI, serial# RR00030718, built 2003: Capmatic dual position tray loader, serial# TT02020846, built 2002.

-

New Sartorius Hipersep Flowdrive Pilot Preparative HPLC Chromatography System, serial number 3998-H, built 2022.

-

Used 10 Liter Diosna high shear mixer, model P/VAC 10/60, stainless steel construction, 10 liter jacketed bowl, side discharge with pneumatic plug valve, with controls, 480 volt, serial# 670-031, built 2005.

-

Used CVC wrap around labeler, model 302C, with dual bump feed wheels, wrap station and PLC controls, 220 volt, serial# 09603075, built 2007.

-

Used M&O Perry inline liquid vial filler, Model P-1510, stainless steel construction, speeds from 35-45 vials/minute, set up with filling, plug inserting and capping stations, Flexicon peristaltic fill pump, V change conveyor, change parts for 13 and 20mm plugs/caps with bowl feeders, vial infeed rotary table, and discharge rotary table, serial# P-888, built 2006.

-

Used Watson Marlow PPT pump system, model MGS, with (2) two Easy Load Masterflex peristaltic pumps, stainless steel enclosure, 230 volt, serial# 021808.

-

Used Symyx Technologies Powdernium automated powder dosing system, model TruFlex 200H, for use with capsules, vials, tubes, wellplates, reactor blocks, crucibles, etc., with robotic filler arm, with parts, 115 volt, serial# TF 07113.

-

Used Aeromatic-Fielder fluid bed dryer, model STREA-1, with stainless steel expansion chamber, no top spray nozzle, 1.5 kw/h heater, 1 hp blower, 110 volt, serial# 11462. As Is.

-

Used AmericanBrand ultrasonic cleaner, model ME4.6, stainless steel construction, 120 volts, serial# 77M12603.

-

Used Cozzoli vial washer, model GW24, stainless steel construction, touch screen controls, with Allan Bradley MicroLogix PLC controller, serial# GW24-56.

-

Unused 3 sq meter / 33 sq ft SP Scientific Lyophilizer freeze dryer, model LyoConstellation S30, 316L stainless steel product contact surfaces with (8) approximately 20" wide x 30" deep shelves, 3" shelf spacing, -55°C - +65°C shelf temp range, top down stoppering, 3.48 sq meter / 37.5 sq ft condenser, skid mounted with 20 hp refrigeration compressor, R410A refrigerant, Leybold vacuum pump, unit is unused from manufacturer, 480 volt, part# 100023909, serial# 3281480.

-

Used 5 liter Key International high shear mixer, model KG5, stainless steel construction, 5 liter, 3 liter and 1 liter non-jacketed bowls, serial# J1-4321.

-

Used 100 liter Feldmeier reactor, stainless steel construction, hinged dish top, dish bottom, rated 60 psi at full vacuum at 350 f internal, jacketed for 120 psi at full vacuum at 350 f, bottom mounted .34 hp magnetic agitator drive, 230/460 volt, on legs, serial# S45002, national board# 2637, built 2003.

-

Used Flexicon vacuum loader, stainless steel construction, hopper receiver with integrated dust collection, Gash rotary lobe blower, model JG136, with 10 hp, 208-230/460 volt motor and rotary air lock.

-

Used Keith Machinery Twin Shell Blender

-

Used ProDieCo Tablet sorter with tooling and EHS Drum Lift, Model CL210, Serial 118061746202

-

Used Agilent gas chromatograph, model 6890A, serial# US00034267 with Agilent 7683 series injector and Hewlett Packard HP 7694 headspace sampler.

-

Used Agilent 1260 Infinity II HPLC System consisting of 1X1260 Isocratic Pump (ISO) serial# DEAEH01141 1X 1200 Analytical Light Scattering (ALS) serial# DE64764961 1X1260 Multicolumn Thermostat (MCT) serial# DEAED10460 1X 1100 Refractive Index Detector (RID) serial# DE43801720.

-

New 50 cu ft AIM Blending ribbon blender, model RB-50, 304 sanitary stainless steel construction, #4 internal finish, buffed matt external finish, 56 cu ft total capacity, 50 cu ft working capacity, approximately 37" wide x 76" long x 42" deep trough, double ribbon agitator, full hinged top cover, outboard roller bearings, sanitary split packing gland shaft seals, 6" center bottom outlet with manually operated slide gate discharge valve, 15 hp, 230/460 volt motor drive producing approximately 45 rpm shaft speed, on 304 stainless steel stand with approximately 5" discharge height, serial# 050-416-SS-FG-RB-6S-2204-15V, built 2022 New and Unused.

-

New 50 cu ft AIM Blending ribbon blender, model RB-50, 304 sanitary stainless steel construction, #4 internal finish, buffed matt external finish, 56 cu ft total capacity, 50 cu ft working capacity, approximately 37" wide x 76" long x 42" deep trough, double ribbon agitator, full hinged top cover, outboard roller bearings, sanitary split packing gland shaft seals, 6" center bottom outlet with manually operated slide gate discharge valve, 15 hp, 230/460 volt motor drive producing approximately 45 rpm shaft speed, on 304 stainless steel stand with approximately 5" discharge height, serial# 050-416-SS-FG-RB-6S-2204-15V, built 2022 New and Unused.

-

Used O'Hara Labcoat 3 O'Hara Labcoat III Coating System. 2005. 18/80 KG@1kh/L Capacity, 60Hz, 460V. Aqueous Use Only. S/N:3710.

-

Used Fitzpatrick D6A 6" Fitzmill. Stainless Steel Auger Feeder. S/N: 12226.

-

Used Ceia THS/PH21N Pharmaceutical Metal Detection System. Made in 2010. S/N: 21000244022.

-

Unused MG2 robotic palletizer, model GRP, 6 axis robot with 50 kg capacity, 15 cycles/minute, 150 x 100 x 100 mm - 600 x 400 x 400 mm case size range, 800 x 1,200 mm (EU), - 1,000 x 1,200 mm (US) pallet size, 1,600 mm max full pallet height (including pallet). Unit is unused, FAT performed.

-

Used Stokes Capsule Polisher, Model 180-8 Capable of 400,000 capsules per hour. Designed for cleaning and polishing hard gelatin capsules in a single step. It eliminates the double handling and extra space requirements of the conventional process using a lamb's-wool belt or salt-and-pan method. This unit produces a finished product well within pharmaceutical standards for cleanliness and brightness. Vacuum required 50 cfm at 21'' static pressure serial# 681140.

-

Used ACG Pam Mini Filled Capsule Sorter, model MCS100, stainless steel construction, 9" x 12" sorting area, serial# MCS-559.

-

Used K-Tron powder delumper hopper, stainless steel construction, with .5 hp, 230/460 volt motor drive with VFD controllers.

-

Used 19 MM APV Baker Perkins twin screw co rotating extruder, model MP-19-TC, 19 mm diameter screws, 40:1 l/d, electrically heated, water cooled barrel, split barrel design, 2 kw dc motor, 500 rpm screw spped, with Ktron main feeder, (2) Brabender auxiliary feeders, (3) Zenith melt pumps, FTS chiller, external control panel, with associated screws, screw elements, control panel, 220 volt, CE rated, APV serial# NEF990028-701/1, Baker Perkins serial# TS99535, project# 99TS196, built 1999.

-

Unused Ktron vacuum loading system, Series 2400, with model 2415 receiver, with bottom mounted slide gate valve, 5 hp roots blower, and fines collector.

-

Used 100 Gallon Ross Triple Motion Vacuum Mixer, model PVM-100, 304 stainless steel construction, anchor agitator with bottom and sidewall scrappers, driven by 10 hp xp motor, disperser driven by 10 hp, xp motor motor, emulsifier driven by 25 hp xp motor, motors 230/460 volt, XP rated class 1, div 2, with (2) 100 gallon stainless steel jacketed mix can, jacket rated 100 psi, vacuum cover, air over oil lift, with Ross DS-100 hydraulic lift and press-out unit, serial# 76747, built 1999.

-

Used 3 cu ft Patterson Kelley twin shell blender, stainless steel construction, rated 85#/cu ft maximum material density, liquid solids bar with motor drive, perforated covers, 6" diameter discharge with valve, on stand with motor drive, serial# 289220.

-

Used Eriez metal detector, model EZ-5, type 8X24HIM, style 9504305, 8" x 24" aperture, with integrated plastic chain conveyor, driven by .5 hp motor, Eriez serial# 145784.

-

Used GlobePharma Mini Blend V-Blender, model MNB-1, with (3) stainless steel shells, 110V, serial# 12066812.

-

Used Korsch rotary tablet press, model PH250/25, 25 station, 20 Kn pre compression, 80 Kn main compression, 16 mm max tablet diameter, 18 mm max depth of fill, single side with force feeder, rated up to 180000 tablets/hour, serial# 1.0031.94, built 1994.

-

Used GEA Niro high shear granulator mixer, model PharmaConnect, Through-The-Wall (TTW) design, stainless steel construction, with (4) interchangeable jacketed PMA style stainless steel mixing bowls all with 3000 rpm choppers, jackets rated 2 bar at 80 c, PMA1 1 liter, 1637 rpm main impeller, PMA3, 2.25 liter, 1134 rpm main impeller, PMA5, 3.75 liter, 953 rpm main impeller, PMA10, 7.5 liter, 756 rpm main impeller, with integrated HMI controls, CE/EX ratings, serial# 09377-1310, built 2010.

-

Used GEA Niro sanitary spray drying system consisting of: Model PSD4 GEA Niro spray dryer, approximately 8' inner diameter x 8'6" straight side x 8'9" deep cone bottom spray dryer chamber, 316 stainless steel product contact surfaces, mirror internal finish, with fluid nozzle and centrifugal rotary atomizers, approximately 17" diameter, sanitary stainless steel cyclone fines collector, approximately 6' diameter dust collector, sanitary stainless steel construction, pulse jet, cone bottom, set up for electric or steam heating with Watlow, 145 kw electric heater with external Hepa filter, air handler with steam coil and Watlow 37.25 kw electric heater, internal Hepa filter, designed for nitrogen purge, 7.5 hp process air supply blower, 7.5 hp process air return blower, set up for solvent recovery with condensor(less receiver pot), solution feed pump with Micro Motion flow meter, inter connecting pipe work from dryer, to dust collector and cyclone, GEA Niro control panel and HMI panel, 460 volt, 3 phase, GEA Niro fabrication# 099-0013-00, built 1999.

-

Used Quadro Comil, model 194, stainless steel construction, with beater and 5 hp, 230/460 volt motor on legs, serial# 194-1373.

-

Used Genesis Machinery crimper, model LW, up to 6" diameter x 8" high vial size range, 110V, serial# LW343, built 2000.

-

Used 4 quart GlobePharma MaxiBlend twin shell blender, model MB-IVV, with (2) 4-quart stainless steel blending shells, 110 volt, serial# 041531248, built 2015.

-

Bausch + Strobel SP-100 Powder filling Machine with control cabinet, stainless steel construction, with filler funnels and auger, serial# 51181, built 1998.

-

Used 50 cu ft Custom Powder Systems bins, model 610185, stainless steel construction, 48" diameter x 36" straight side, approximately 30" cone, with 20" top access, 8" bottom outlet, on framework stand with provisions for forks, serial#s 5538-9, 5538-2, 5538-13, 5538-5, 5538-3.

-

GlobePharma MaxiBlend, model MB-IVV twin shell blender, with (2) 4-quart blending shells, 110-120 volt, serial# 041531248, built 2015.

-

Used IMA capsule checkweigher, model Precisa 120, designed to handle hard gelatine capsules, rated up to 120,000 capsules/hour, capsule size range from 40 mg to 2000 mg, +/- 2 mg accuracy, serial# PA1031, built 1999.

-

Used 125 liter Integrated Biosystems Cryovessel, 316L stainless steel construction, approximately 20" diameter x 30" straight side, removable dish top dish bottom, internal rated 50 psi and full vacuum at 280 F/ 15 psi at -112 F, jacket rated 65 psi and full vacuum at 280/-112F, with central heat exchanger arranged in (X) orientation, rated 65 psi and full vacuum at 280/-112F, with forklift access, certified by Precision Stainless, serial# 202458-2, National Board# 9243, built 2001.

-

Used IMA Switftpack lane counter, model SPCB12P3PTS Twin, dual 12 lanes each heads mounted on common frame, 230 volt, serial# M4961, built 2007.

CONTACT INFORMATION

Federal Equipment Company

8200 Bessemer Avenue

Cleveland, OH 44127

UNITED STATES

Phone: 216-271-3500

Fax: 216-271-5210

FEATURED ARTICLES

DECONTAMINATION SERVICES

-

Pharmaceutical, biopharmaceutical, supplement, chemical, food, and beverage manufacturing all rely on knowing that equipment is clean and decontaminated before going into production. Not sure where that equipment has been? Or do you need to demonstrate an equipment decontamination process and procedure? Allow Federal Equipment Company to help with our Decontamination Services.

CAPSULE FILLERS

-

Capsugel Xcelodose 600 Capsule Filler with Xcelotable, CE rated, serial# 600-1-039.

-

Used MG2 Planeta 100 continuous motion capsule filler with touch screen HMI, vacuum system, serial# 4661, built 2010.

-

Used IMA Precisa 18 tablet/capsule checkweigher. Made in 2003. Size 2 change parts. With Becker vacuum pump. S/N: PA1099.

-

Used Anritsu capsule checkweigher, model KW9001AP, 16 lanes, up to 2000/minute, with size 0 tooling, CE rated, serial# 4600087249, built 2008.

-

Used Shionogi Qualicaps quali-fill capsule filling machine, serial# 96-F40.

-

Used ACG-Pam Capsule Filler, Model AFT LAB.

-

Used Sejong Encapsulator, with change parts/tooling, 600 volts, 3 phase.

-

Federal Equipment Company sells used capsule filling equipment commonly used for the production of pharmaceuticals, nutraceutical, vitamins and supplements. Search our entire inventory of used capsule filling equipment for a full suite of used capsule filling equipment including hard-gel capsule fillers, soft-gel capsule fillers, capsule checkweighers, capsule polishers, as well as capsule tooling and change parts. You will find top manufacturers here like IMA, Syntegon (formerly Bosch), Capsugel, Dott.Bonapace, MG2, and many others.

-

One (1) used Capsugel Xcelodose 120 capsule filler with controller and associated tooling. Unit is CE rated.

-

One (1) used IMA Zanasi 40F capsule filler with change parts for capsule sizes 3 and 4. Unit requires 220 voltage.

COATERS

-

30" Vector Hi-Coater Coating Pan, stainless steel construction, for model VHC-1355 coater, built 2002.

CHECKWEIGHERS

-

Used Mettler Toledo Hi-Speed Checkweigher model Starweigh XS Tare, with Typ X-Terminal-HMI/HI-SPEED controller, part# 100227, serial# 10022712.

-

Used IMA capsule checkweigher, model Precisa 120, designed to handle hard gelatine capsules, rated up to 120,000 capsules/hour, capsule size range from 40 mg to 2000 mg, +/- 2 mg accuracy, change parts for 00,0,1,2,3,4 and Supro B with vacuum pump, serial# PA1009, built 1997.

MILLS

-

Used Bematek colloid milL, model CBT-50-PB-1, serial# 16-4703.

-

Used Hanningfield Process Systems cone mill, model M10U, stainless steel construction, underdriven with approximately 2 hp motor, 3600 rpm with integrated Loma flow thru metalcheck, model IQ4 Wafer, Loma serial# W46TDVD1SNT-48166D, Hanningfield serial# M10-U-0133, built 2019.

-

Used Fuji Paudal Marumerizer spheronizer, model QJ700, stainless steel construction, with 2.0 mm grooved spheronizing plate with plate lift mechanism, jacketed bowl, side discharge with pneumatically operated plug valve, on base, serial 20050, built 1990.

-

One (1) used Quadro Comil mounted in isolator, model U10, stainless steel construction, missing beater and screen, direct coupled 20 hp, 230/460 volt xp motor with vfd controller mounted in xp panel, unit mounted in Carlisle Life Science isolator, stainless steel construction, single sided with (5) glove ports, approximately 60" long x 22" deep x 43" high, with 10" diameter end access door, on stand.

ISOLATORS / CONTAINMENT

-

One (1) Unused Howorth isolator, 316L stainless steel construction, approximately 9'6" long x 24" deep x 36" high inside chamber, single sided, 6 gloves with side access door, (2) 16" X 29" side access doors, 18" bottom outlet with cover, 4" bottom outlet with cover, CIP spray balls, (2) top mounted internal lights, 1 hp, 230/460 volt blower, on stainless steel stands with control panel, serial# 4344-200, new 2009.

BLENDERS & MIXERS

-